Chemical modified plastics

The second phase project adopts multiple balance weight forklift AGVs to complete unmanned handling of multiple floors on the first floor. Through a closed-loop system, real-time uploading of product inventory status, outbound information, equipment status, etc. is achieved to create visual management of information flow.

Quantity

7 units

Step

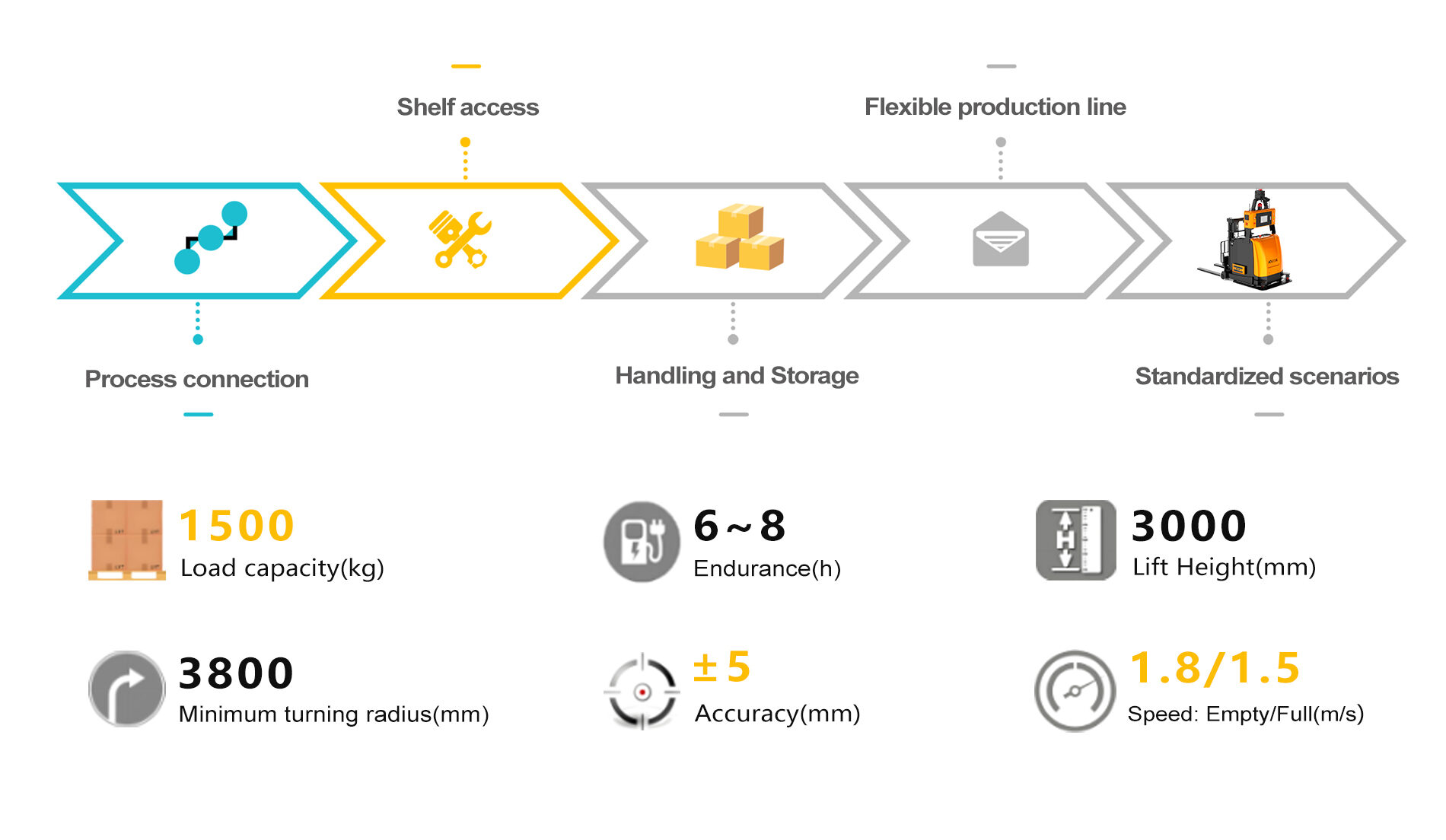

Warehouse handling

Address

East China

Difficulty

Cross floor

Usage scenarios

Advantage

Full dynamic laser SLAM navigation technology, real-time mapping and positioning (accuracy ±10mm), adaptable to complex dynamic environments (such as mixed pedestrian and vehicle traffic, outdoor), supports real-time map updates and flexible path planning.

The ability to quickly build a map and adjust paths within 15 minutes, adapting to layout changes in a multi-batch and small-batch production mode.

Integrated with 3D vision, LiDAR and mechanical anti-collision devices, the detection range is 0-3m, supporting active avoidance and emergency stop in human-machine mixed environments.

The real-time monitoring of the vehicle body status through the AIDT digital twin platform has shortened the response time for fault warnings to within five minutes.

Related Products

V05OT

M20OR

V20F

-V05OT-800x800.png)